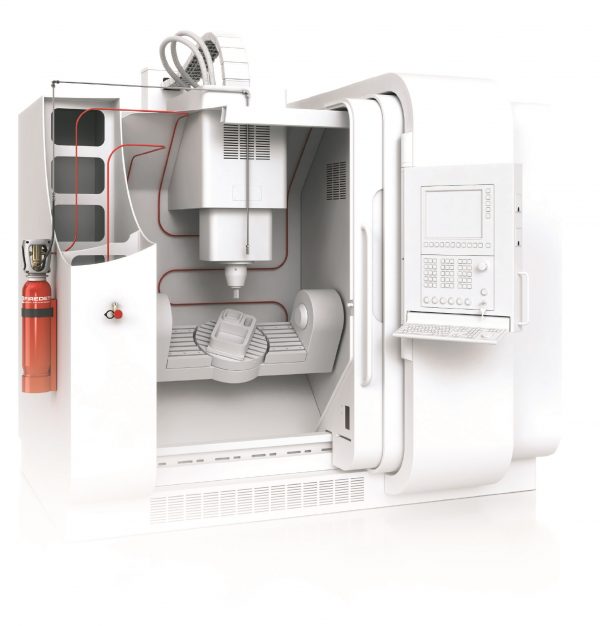

Fire Extinguishing System For CNC Machinery

MOBIAK, a pioneer in extinguishing systems, proposes an Integrated Solution – pre-engineered, for the confrontation of fire hazard in cnc machines

- CO2 or FM-200 Extinguishing Material

- Easy / flexible installation

- Fast & Reliable extinguishing

- Independent operation of electricity and moving parts

Financial Installation Reduces the most critical risks and prevents the results of a possible fire, such as:

- The combustion of oil residues or mechanical parts due to a malfunction of the cooling system or insufficient maintenance.

- Extensive repairs of the machine, in case of ignition.

- Delay in order servicing due to interruption of production.

- Extensive cleaning, in case the central sprinkler system is activated

THE DIFFERENCE OF FIREDETEC® FireDETEC Systems® use a Heat Sensitive Linear Heat Detection Fussible Tube which is under Pressure of 16Bar with Nitrogen Gas (or Ambient Air) and melts at 110ºC by activating the System.

The detection system is very flexible in installation, effective in covering the sensitive space that needs to be protected and more economical against alternative systems with mechanical electronic detection systems. 1. Quick and easy installation directly inside the CNC machines: The Heat-Sensitive Fussible Tube is easily installed in the area of the CNC machine tool. The Pressure of the Heat-Sensitive Fussible Tube is 16bar. As soon as the activation temperature occurs the tube melts and the drop in pressure activates the system. 2. Early fire detection: The heat of the fire causes an increase in pressure inside the pipe which melts at about 110ºC.). 3. Immediate extinguishing: The sudden pressure drop of the pipe activates the special differential pressure valve and immediately the extinguishing material (CO2 or FM-200) is released throughout the machine. The fire is suppressed in a few seconds after its appearance, minimizing the damage and the time of possible interruption of production. CERTIFIED IN ITS ENTIRETY BY UL & FM